Membrane Bioreactor System Brief

Membrane bioreactor technology (MBR) is a relatively new wastewater treatment technology, based on a combination of membrane separation and biodegradation; it uses membrane separation to keep large biosolids and useful microorganism inside the reaction tank. It allows achieving higher concentration of activated sludge, improving solids retention. MBR is currently one of the most promising wastewater treatment technologies widely used in Japan, France, US, Canada, and other countries.

MBR ADVANTAGES

1. Low footprint and construction area;

2. Excellent effluent quality and solids retention; SDI≤3;

3. Enhanced biological degradation and treatment efficiency; lower operational cost;

4. Better nutrients removal and ammonia oxidation;

5. Modular design and flexible operation.

MBR PROCESS FLOWCHART

COMPONENTS

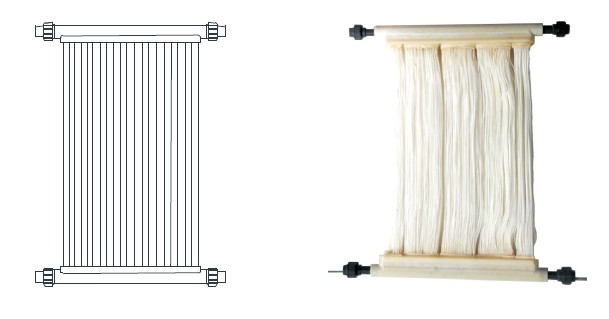

MBR system consist of three main elements: pretreatment, biological reactor, and disinfection. MBR biological reactor is similar to the conventional bioreactor, but it includes the UF membrane module for solids separation. UF separation unit is utilized to retain active sludge in the reactor, and is composed of following elements:

1) UF membrane – core element;

2) Pump system – feed/lifting pumps, suction pumps;

3) Backwash system: backwash pump and backwash tank;

4) Chemical dosing system for membrane cleaning;

5) Aeration system for aeration tank;

6) Valves and piping.

MBR SYSTEM FEATURES

1. Excellent effluent quality; no need for secondary sedimentation or filtration;

2. Small footprint, 50-75% less than conventional activated sludge (CAS) approach;

3. Lower operational costs, power consumption, flocculant and disinfectant usage;

4. High process impact resistance and flexibility;

5. Lower sludge production and higher solids retention;

7. Fully automatic operation and control, optional remote control system;

8. Modular design and integration; due to its low footprint, MBR is much easier to integrate into the existing system or combine with other treatment methods.

MBR MEMBRANE FEATURES

1. High flux rate, up to 55 LMH (L/m2*H). Asymmetric membrane structure reduces flow resistance, and improves hydraulic properties and permeability;

2. Reinforced PVDF membrane structure for mechanical strength. Membranes are less susceptible to being damaged during the filtration, backwashing or chemical cleaning;

3. Unique anti-fouling design; specific design of aeration nozzles prevents extensive membrane fouling, extending the operation time;

4. Wide range of membrane sizes and configurations for optimal system design;

5. Sealed fiber end design; bottom end of each hollow fiber is sealed; permeate is collected through the top opening preventing the contamination of clean water with sludge and bacteria;

6. Stable operation and long service life.