SUEZ E-CELL of longevity EDI

- Download -

- Download -

In an article about EDR, I mentioned that there are actually many members of SUEZ’s electrodialysis longevity family, and they all perform their own duties and focus on different fields. So today I might as well introduce to you an expert in EDI technology that is unrivaled in electric power, pharmaceuticals and semiconductor ultrapure water treatment. It also has a cool name: E-Cell.

We sell Suez now Veolia, EDI Stack E-Cell- MK-7

EDI principle

EDI (Electrodeionization) is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology and ion electromigration technology. It cleverly combines electrodialysis and ion exchange technology, uses high voltage at both ends of the electrodes to move charged ions in the water, and cooperates with ion exchange resin and selective

resin membrane to accelerate the movement and removal of ions, thereby achieving the purpose of water purification.

Advantages of Electrodeionization EDI Technology

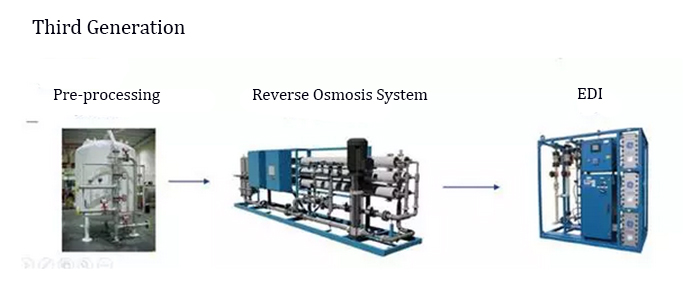

The deionized water process has roughly gone through three generations:

✦First generation: pretreatment + cation and anion exchange resin + mixed bed. However, the cost of water produced by this method is high, and there are too many particle impurities, which cannot meet the ideal requirements. It is rarely used now.

✦Second generation: pretreatment + reverse osmosis + mixed bed process. This is the more popular method currently.

✦Third generation: pretreatment + reverse osmosis + EDI process. Compared with mixed beds, the advantages of EDI technology are:

➤No chemical regeneration required

The acid and alkali required for mixed bed regeneration need to be transported, stored and processed, but using EDI does not require the transportation and storage of dangerous chemicals, and the operation is safer.

➤Can run continuously and is easy to operate

The use of EDI can eliminate the disadvantages of intermittent operation and ensure continuous and stable water quality. No manual intervention by the operator is required, and no complicated operating steps are required.

We sell Suez now Veolia, EDI Stack E-Cell- MK-7

➤Reduce equipment footprint

The combination of RO and EDI occupies a small area, requires the smallest reserved space for the system, does not require a high factory building, and is light in weight for transportation and installation.

➤No harmful wastewater discharge

Using EDI no longer requires a waste acid/alkali neutralization tank, and concentrated water discharge can be recycled, which is more environmentally friendly.

The difference between E-Cell and other brands of EDI

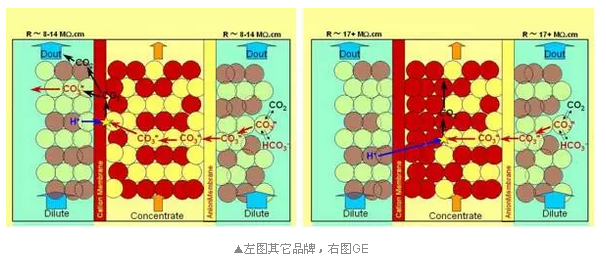

Resin arrangement makes water removal more efficient

The resin arrangement structure of other brands of EDI concentrated water chambers will cause CO2 to flow back from the concentrated water chamber to the fresh water chamber, which may lead to a decrease in the quality of the EDI produced water. E-Cell's unique resin arrangement structure in the concentrated water chamber can prevent CO2 backflow and ensure water output.

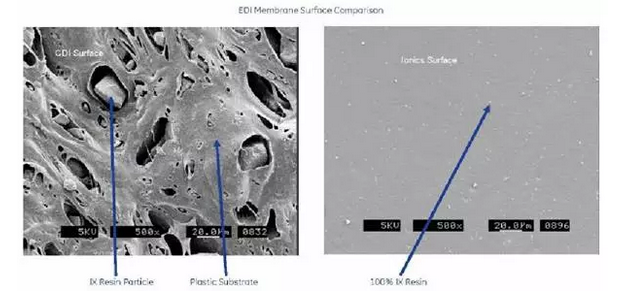

Smoother diaphragm

E-Cell membranes are smoother than other membranes, thereby reducing the probability of scaling and bacterial growth caused by residual contaminants.

Two-in and three-out design

It adopts a two-inlet and three-outlet design to separate extreme water from concentrated water, which improves the safety factor of the system compared with other brands' two-inlet and two-outlet designs.

lowest running costs

The energy consumption of the E-Cell MK-3 system is only 0.132-0.396KWhr/t. Under normal operation, the operating voltage is 50-80V and the current is 1-1.5A. Moreover, when using a counter-flow module design, the water inlet pressure of E-Cell is lower.

Silica removal ability

E-Cell's silica removal rate is as high as 96%-99%, which is significantly higher than other brands.

The produced water resistivity is higher

The maximum water production value of E-Cell's modules is more than 17 trillion, while the maximum water production value of other brands is more than 15 trillion.

Modules have stronger recovery capabilities after cleaning

Usually, E-Cell module cleaning and regeneration water can still reach more than 17 trillion, while the recovery rates of other brands are worse than E-Cell.

We sell Suez now Veolia, EDI Stack E-Cell- MK-7

Because of the above-mentioned outstanding performance, SUEZ E-Cell has become the best choice for users. Let me speak with a case:

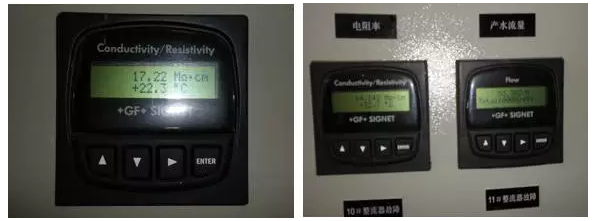

Case of a power plant in Shandong

A power plant in Shandong adopts ultrafiltration UF + first-level RO + EDI process, with a water production capacity of 4*55T/H (4×16 EDI modules). In the early days of building the factory, a company's roll-type EDI was used. Due to high power consumption, frequent maintenance, and high maintenance costs, the factory replaced it with a domestic brand in 2009. Because it could not operate normally, in 2010, two systems were renovated simultaneously using GE and another foreign brand to compare the operation of the two systems and accumulate data for the next phase of the remodeling. As a result, GE E-cell outperformed the other company in terms of water quality, quantity and power consumption, and the remaining two sets were eventually replaced with GE E-Cell. Here is a comparison of the two sets of equipment:

Left: GE E-Cell 16 module system Right: A competitor’s 16 module system

Left: The operating voltage of E-Cell is about 100V, and the current is about 2.0A; Right: The voltage of a competitor is about 250V, and the current is 3A.