Veolia™ E-Cell* EDI MK-3PharmHT Stack edi module Flow 3.4 m³/h (15 gpm), A Conductivity Below 109µs/Cm edi systems

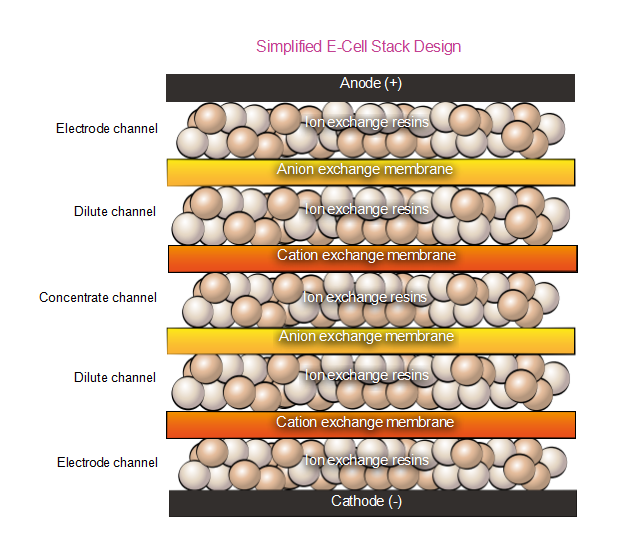

Veolia's E-Cell* electrodeionization (EDI) technology efficiently removes residual salts and ionizable species like carbon dioxide, silica, ammonia, and boron from water sources. Central to this technology is the EDI stack, and Veolia offers diverse options to suit a wide range of applications. Additionally, they provide pre-engineered EDI systems for convenience. Whether you choose to purchase E-Cell stacks or a comprehensive system, Veolia's expertise, global reach, and proven performance guarantee reliable ultrapure or high purity water solutions.

Parameter data

Brand | Veolia EDI |

Exchangeable ppm | 63.6 |

Inlet Pressure bar | 6.9 |

Inlet Pressure psi | 100 |

Max Temperature °C | 40 |

Max Temperature °F | 104 |

Pressure drop bar | 1,4-2,8 |

Pressure drop psi | 20-40 |

Recovery % | up to 96 % |

Conductivity µs/cm | < 109 |

pH range | 4-11 |

Flow m3/h | 1,6-5,4 |

Flow rate gpm/ft2 | 7,0-23,8 |

Power voltage V | 0-300 VDC |

Shipping Weight kg | 100 |

Shipping Weight lbs | 220 |

Application | Water for injection, Pharmaceutical, Laboratory |

Please see below for detailed parameters

General Description

The E-Cell MK-3PharmHT Stack, a component of the E-Cell* electrodeionization product line, is specifically engineered to:

* Leverage electrical current to generate ultrapure water tailored for the pharmaceutical and biotechnology sectors.

* Withstand sanitization with hot water up to 185ºF (85ºC) for up to 160 cycles.

* Achieve top-tier performance, including the highest water quality standards and optimized energy efficiency.

* Minimize cleaning frequency even at elevated feed water hardness through counter-current operation.

* Guarantee leak-free operation backed by a standard 3-year prorated warranty.

* Operate seamlessly and continuously, eliminating the need for caustic or acid in regenerating the ion exchange resin within the stack.

* Eliminate the requirement for brine injection or concentrate recirculation.

The following figure shows GE, Suez and Veolia from left to right (all the same product: Veolia EDI Module)

Typical Applications

The E-Cell MK-3PharmHT Stack produces ultrapure water that consistently surpasses the quality standards set by USP, EP, and other pharmacopeias in a range of applications. Its trusted usage includes:

* Producing water for injection purposes.

* Supplying pharmaceutical-grade purified water.

* Serving as a source for laboratory-grade purified water systems.

To simplify the design process and further enhance confidence in your EDI application, Veolia offers performance projections and guarantees for the E-Cell MK-3PharmHT through the Winflows* software or by direct contact.

Quality Assurance

The E-Cell MK-3PharmHT Stack assures exceptional quality with multiple certifications and compliances:

* CE, RoHS, CSA, and EAC markings for safety and environmental compliance.

* All materials in contact with fluids processed by the stack adhere to FDA regulations, ensuring safety for pharmaceutical and biotechnology applications.

* UKCA certification for conformity with British standards.

* Manufactured in an ISO 9001 and ISO 14001 facility, guaranteeing high-quality production processes and environmental sustainability.

* Halal certification by the Islamic Food and Nutrition Council of America (IFANCA®), ensuring compliance with Islamic dietary laws.

These assurances provide peace of mind in adopting the E-Cell MK-3PharmHT Stack for your ultrapure water needs.

MK-3PharmHT Stack Specifications |

Nominal Flow | 3.4 m3/h (15 gpm) |

Flow Rate Range | 1.6–5.4 m3/h (7.0–23.8 gpm) |

Shipping Weight | 100 kg (220 lbs) |

Dimensions (width x height x depth) | 30 cm x 61 cm x 54 cm 12’’ x 24” x 22” |

Product Water Quality Note 1 |

Guarantees Available |

Resistivity | ≥ 10 MOhm-cm |

Typical Removal Efficiencies |

Sodium | ≥ 99.9% removal |

Silica (SiO2) | Up to 99% removal |

Operating Parameters |

Recovery | Up to 96% |

Voltage | 0–300 VDC |

Amperage | 0–5.2 ADC |

Inlet Pressure Note 2 | ≤ 6.9 bar (100 psi) |

Pressure Drop Note 3 | 1.4–2.8 bar | 20–40 psi |

Hot Water Sanitization Cycles | 160 |

Maximum Sanitization Temperature | 85ºC (185ºF) |

Maximum Sanitization Inlet Pressure | 2.1 bar (30 psi) |

Feed Water Specifications Note 4 |

Total Exchangeable Anions (TEA as CaCO3) Note 5 | ≤ 63.6 ppm |

Conductivity Equivalent | ≤ 109 μS/cm |

Temperature | 4.4–40˚C (40–104˚F) |

Total Hardness (as CaCO3) Note 6 | ≤ 1.0 ppm |

Silica (SiO2) Note 7 | ≤ 1.0 ppm |

Total Organic Carbon (TOC as C) | ≤ 0.5 ppm |

Total Chlorine | ≤ 0.05 ppm |

Fe, Mn, H2S | ≤ 0.01 ppm |

Boron Note 8 | ≤ 1.0 ppm |

pH | 4 to 11 |

Oil & Grease | None detectable |

Particulate Note 9 | RO permeate |

Oxidizing Agents | None detectable |

Color Note 10 | ≤ 5 APHA |

Notes on Operating and Using the E-Cell MK-3PharmHT Stack:

1. Performance Variations: Actual performance may deviate based on specific site conditions. Use the Winflows projection software to assess the expected water quality, resistivity, sodium, and silica performance guarantees tailored to your design conditions. For boron or additional guarantees, please contact Veolia.

2. Inlet Pressure Determination: Inlet pressure is influenced by the downstream pressure requirements for the product and concentrate streams, the choice of counter-current or co-current operation, and the pressure drop across the stack.

3. Nominal Conditions: All specifications are given at nominal flow rates and 25°C. Refer to the Winflows projection software for design-specific verification.

4. Feed Water Specifications: Verify the feed water specifications for your design conditions using the Winflows projection software and the E-Cell Stack Owner’s Manual.

5. TEA (Total Exchangeable Anion): TEA represents the collective concentration of all anions present in the feed water, including contributions from OH-, CO2, and SiO2. It's essential to use Winflows to ensure the feed water TEA is acceptable under the specific operating conditions of the application. The tabulated value is provided at minimum flow and maximum temperature.

6. Feed Water Hardness Limits: The 1.0 ppm as CaCO3 feed water hardness limit applies specifically to standard counter-current flow operation. When operating in co-current flow, the allowable feed water hardness decreases to 0.1 ppm as CaCO3.

7. Silica Limit Considerations: The permissible silica limit decreases as flow exceeds nominal values. Additionally, if the feedwater hardness exceeds 0.5 ppm as CaCO3, the allowable silica limit decreases to 0.5 ppm.

8. Boron Feed Level: The boron feed level must not exceed 0.3 ppm as B whenever there is a silica guarantee requirement or a resistivity guarantee requirement above 10 MOhm-cm. Higher boron levels can compromise performance. In the absence of these requirements, the limit is 1.0 ppm boron.

9. Reverse Osmosis or Equivalent Feed Water: RO is recommended as it provides EDI feed water that is largely free of particulate matter, colloidal material, and high molecular weight organic substances that can foul ion exchange media. This is crucial as EDI stacks cannot be backwashed/fluidized to remove particulate matter. Systems with an open configuration between RO (or another source) and the E-Cell must include filters upstream of the E-Cell to protect against particulate contamination. Typically, a 5 µm absolute or 1 µm nominal filter is suitable.

10. APHA Color Standard: APHA refers to the color standard/scale named for the American Public Health Association and is defined by ASTM D1209.

Please refer to the Winflows projection software and other relevant documentation for detailed and specific information regarding the operation and maintenance of the E-Cell MK-3PharmHT Stack.

For more models, please click: https://www.fgwater.com/Veolia-Electrodeionization-EDI-Stack-Module/389.html

E-Cell EDI Technology Performance Examples

E-Cell EDI technology has been successfully applied in various industries such as power, petroleum, chemical, steel, pharmaceutical, and electronics.

For application cases, please click:https://www.fgwater.com/Industries/

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.