Evoqua CEDI IP-LXM10Z-4 Industrial Electrodeionization Module Application Industrial / Power 4-11pH range

The VNX module was crafted to minimize the expenditure of constructing high-flow-rate CEDI (Continuous Electrodeionization) systems, along with facilitating a smooth transition towards adopting a clean, environmentally sustainable technology as opposed to chemically regenerated mixed bed ion exchange systems. The incorporation of higher flow rate CEDI modules simplifies piping arrangements and system integration by diminishing the necessary module count.

Furthermore, the VNX modules incorporate an integrated support system, facilitating intelligent skid design and minimizing the associated costs. On the other hand, the Ionpure LX modules are tailored for industrial use, offering unparalleled reliability and outstanding performance in applications ranging from power generation, HPI/CPI (High-Purity Industrial/Commercial Industrial), general electronics, food and beverage processing, to laboratory settings, all without the need for regeneration downtime.

Meanwhile, the Ionpure MX Series of CEDI modules excel in laboratory environments and low-flow process applications. These MX modules serve as a perfect addition to wall-mounted or cabinet-housed RO (Reverse Osmosis) systems in light industrial, commercial, and laboratory settings.

product data

Brand | Evoqua |

Replaced by | IP-LXM10X-4 |

Type | CEDI |

pH range | 4-11 |

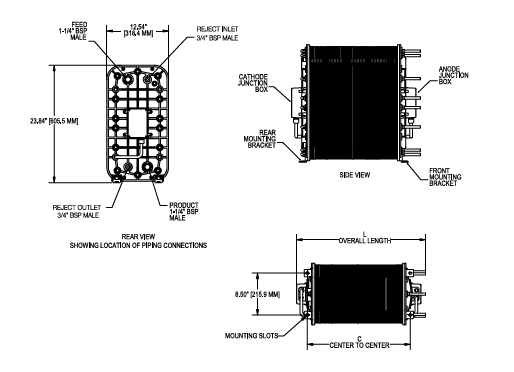

Length in inch | 13.69 |

Length in cm | 34.8 |

Shipping Weight kg | 91 |

Shipping Weight lbs | 200 |

Application | Industrial / Power |

See below for more parameters

QUALITY ASSURANCE STANDARDS

CE mark certification, each module is strictly tested before leaving the factory to meet the high standards of the industry and is manufactured under the conditions of complying with ISO 9001 and ISO 14000 quality and environmental management system standards.

IONPURE LX-Z module has the following significant advantages:

* Wide flow range, single module flow rate from 0.22 cubic meters/hour (1 gallon/minute) to 10 cubic meters/hour (44 gallons/minute), meeting the needs of various application scenarios.

* Significantly lower operating costs compared to traditional ion exchange methods.

* No need to use chemicals to generate mixed-bed quality deionized water.

* Achieve continuous production rather than batch processing to ensure stable and reliable water quality.

* Adopt double O-ring sealing design to ensure leak-free operation.

* No acid, base, neutralization system or replaceable deionized water tank required.

* Filled with premium resin for optimal performance and ease of operation.

* Support continuous operation to ensure uninterrupted water supply.

* Can handle incoming water up to 0.05ppm (total chloride ion content).

* The material of wet parts complies with NSF® 14 and NSF® 61 standards, which is safe and reliable.

About the operating environment of the IONPURE LX-Z module:

The module should be installed indoors, away from direct sunlight, and ensure that the ambient temperature does not exceed 113°F (45°C) to ensure its stable and efficient operation. This can effectively extend the service life of the module while ensuring the stability and reliability of the water quality.

TYPICAL MODULE PERFORMANCE |

Operating Parameters |

|

Recovery | 90–95% |

DC Voltage | 0–400 |

DC Amperage | 1.0–6.0 |

Product Water Quality |

|

Product Resistivity | Minimum Flow > 17 MW-cm*† Maximum Flow > 7 MW-cm*† |

Silica (SiO2) Removal | 90–99%, depending on feed conditions |

* Actual performance can be accurately estimated using the IP-Pro prediction tool provided by Ionpure.

*Performance data is based on testing at the maximum inlet water conductivity equivalent value (40 μS/cm), ensuring excellent deionization results in various application scenarios.

FEED WATER SPECIFICATIONS |

Feed Water Conductivity Equivalent, including CO2 and Silica | < 40 μS/cm |

Feed Water Source | RO permeate |

Temperature | 5–45˚C (41–113˚F) |

Inlet Pressure | 1.4–6.9 bar (20–100 psig) |

Maximum Total Chlorine (as Cl2) | < 0.05 ppm |

Iron (as Fe) | < 0.01 ppm |

Manganese (as Mn) | < 0.01 ppm |

Sulfide (S2-) | < 0.01 ppm |

pH | 4–11 |

Total Hardness (as CaCO3) | < 1.0 ppm |

Dissolved Organics (TOC as C) | < 0.5 ppm |

Silica (SiO2) | < 1.0 ppm |

E-Cell EDI Technology Performance Examples

E-Cell EDI technology has been successfully applied in various industries such as power, petroleum, chemical, steel, pharmaceutical, and electronics.

For application cases, please click:https://www.fgwater.com/Industries/

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.