IONPURE CEDI Module IP-LXM18Z-5 edi module Dissolved organic matter Minimum Flow > 17 MW-cm Maximum Flow > 7 MW-cm

IP-LXM18Z is a commonly utilized model of the American IONPURE Siemens EDI module. This EDI module boasts a water output exceeding 1T/H and is capable of operating continuously for 24 hours. It features a long service life and high water quality. Provided that the inlet water quality meets the requirements, it can attain pure water with a resistivity of over 17MΩ.

Siemens EDI module IP-LXM18Z parameters

Brand: | Siemens IONPURE |

Minimum water flow rate m3/h (gpm): | 1.1 (4.5) |

Nominal water flow rate m3/h (gpm): | 2.0 (9.0) |

Designed water flow rate range m3/h (gpm): | 2.0-3.1 (9.0-13.5) |

Shipping weight kg (lbs): | 99 (217) |

Operating weight kg (lbs): | 74 (163) |

L (mm): | 488.2 |

Installation slot center distance (mm): | 353.8 |

DC voltage: | 0-300V |

Inlet water conductivity: | < 40 pS/cm |

Recovery rate: | 90-95% |

Maximum allowable water inlet pressure: | 7 bar (100 psi) |

Pressure drop range at nominal water flow rate: | 1.7-2.5 bar (25-37 psi) |

Maximum allowable water inlet temperature: | 45°C (113°F) |

Water resistivity |

Minimum water flow rate: | 17 MΩ |

Nominal water flow rate: | 15 MΩ |

Maximum water flow rate: | 7 MΩ |

Silicon (SiO2) removal rate: | 90-99% |

Influent parameters

Influent water source: | RO produced water |

Temperature: | 5-45℃ (41-113℉) |

Influent pressure: | 1.4-7bar (20-100psi) |

Maximum total nitrogen (as Cl2): | <0.02ppm |

Iron (as Fe): | <0.01ppm |

Manganese (as Mn): | <0.01ppm |

Sulfide (S2-): | <0.01ppm |

pH value: | 4-11 |

Total hardness (as CaCO3): | <1.0ppm |

Dissolved organic matter (TOC, as C): | <0.5ppm |

Silicon (as SiO2): | <1.0ppm |

Siemens EDI module IP-LXM18Z structural features

Siemens EDI module is a device composed of resin and membrane chamber. Because it utilizes the principle of electrodialysis, EDI module is also called electrodialysis device.

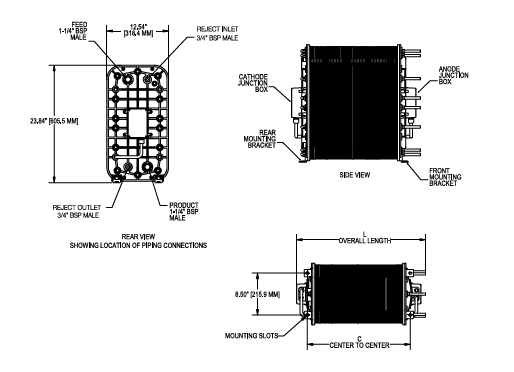

Siemens IP-LXM18Z module is mainly composed of feed liquid pretreatment system, membrane stack pretreatment system, membrane stack, electrode, process control system and power system.

According to the structural diagram, EDI membrane stack is composed of a certain number of units sandwiched between two electrodes. There are two different types of chambers in each unit, the fresh water chamber to be desalted and the concentrated water chamber to collect the removed impurity ions.

Working principle of Siemens EDI module IP-LXM18Z

Siemens EDI module IP-LXM18Z uses anion and cation exchange membranes alternately arranged between positive and negative electrodes, and separates them with special partitions to form two systems: desalination and concentration. When brine is introduced into the compartment, under the action of the DC electric field, cations migrate to the cathode and can only pass through the cation exchange membrane, and anions migrate to the anode and can only pass through the anion exchange membrane, so that the brine in the desalination chamber is desalinated and the brine in the concentration chamber is concentrated.

This technology of using electrolyzed water for ion replacement is called electro-deionization EDI technology. It relies on the action of the electric field to remove inorganic ions in water. It is a new pure water preparation technology that has emerged in recent years. The advantages of this technology are very prominent. It solves the shortcomings of electrodialysis that cannot desalinate deeply, and can ensure that ion exchange works continuously. It can operate 24 hours a day, and the water quality of the produced water is stable, which can meet the requirements of ultrapure water and boiler water for resistivity, hardness and silicon.

The LX-Z series membrane stack is an industrial CEDI developed by Siemens for industrial wastewater desalination and industrial ultrapure water deionization. The EDI has a long service life and can run continuously to meet industrial production needs without stopping for regeneration. However, Siemens EDI also has high requirements for the quality of influent water. When using Siemens EDI, you must choose a reliable agent that can provide comprehensive after-sales service.

QUALITY ASSURANCE STANDARDS

CE mark certification, each module is strictly tested before leaving the factory to meet the high standards of the industry and is manufactured under the conditions of complying with ISO 9001 and ISO 14000 quality and environmental management system standards.

IONPURE LX-Z module has the following significant advantages:

* Wide flow range, single module flow rate from 0.22 cubic meters/hour (1 gallon/minute) to 10 cubic meters/hour (44 gallons/minute), meeting the needs of various application scenarios.

* Significantly lower operating costs compared to traditional ion exchange methods.

* No need to use chemicals to generate mixed-bed quality deionized water.

* Achieve continuous production rather than batch processing to ensure stable and reliable water quality.

* Adopt double O-ring sealing design to ensure leak-free operation.

* No acid, base, neutralization system or replaceable deionized water tank required.

* Filled with premium resin for optimal performance and ease of operation.

* Support continuous operation to ensure uninterrupted water supply.

* Can handle incoming water up to 0.05ppm (total chloride ion content).

* The material of wet parts complies with NSF® 14 and NSF® 61 standards, which is safe and reliable.

About the operating environment of the IONPURE LX-Z module:

The module should be installed indoors, away from direct sunlight, and ensure that the ambient temperature does not exceed 113°F (45°C) to ensure its stable and efficient operation. This can effectively extend the service life of the module while ensuring the stability and reliability of the water quality.

TYPICAL MODULE PERFORMANCE |

Operating Parameters |

|

Recovery | 90–95% |

DC Voltage | 0–400 |

DC Amperage | 1.0–6.0 |

Product Water Quality |

|

Product Resistivity | Minimum Flow > 17 MW-cm*† Maximum Flow > 7 MW-cm*† |

Silica (SiO2) Removal | 90–99%, depending on feed conditions |

* Actual performance can be accurately estimated using the IP-Pro prediction tool provided by Ionpure.

*Performance data is based on testing at the maximum inlet water conductivity equivalent value (40 μS/cm), ensuring excellent deionization results in various application scenarios.

FEED WATER SPECIFICATIONS |

Feed Water Conductivity Equivalent, including CO2 and Silica | < 40 μS/cm |

Feed Water Source | RO permeate |

Temperature | 5–45˚C (41–113˚F) |

Inlet Pressure | 1.4–6.9 bar (20–100 psig) |

Maximum Total Chlorine (as Cl2) | < 0.05 ppm |

Iron (as Fe) | < 0.01 ppm |

Manganese (as Mn) | < 0.01 ppm |

Sulfide (S2-) | < 0.01 ppm |

pH | 4–11 |

Total Hardness (as CaCO3) | < 1.0 ppm |

Dissolved Organics (TOC as C) | < 0.5 ppm |

Silica (SiO2) | < 1.0 ppm |

E-Cell EDI Technology Performance Examples

E-Cell EDI technology has been successfully applied in various industries such as power, petroleum, chemical, steel, pharmaceutical, and electronics.

For application cases, please click:https://www.fgwater.com/Industries/

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.