Multimedia filter tanks for water pretreatment

Carbon Filter Media Tanks

Carbon filters are used to remove organics (as TOC) and free chlorine from RO feed water. Bituminous carbon is used for industrial RO pretreatment applications.

Organics are adsorbed on carbon particles for removal from water. Removal of chlorine involves an oxidation/reduction reaction with the carbon particles, where a transfer of electrons occurs from the activated carbon to the chlorine (the carbon acts as a reducing agent). Design fl ow rates should be 1 GPM/ft3 for TOC removal and 2 GPM/ft3 for chlorine removal when used for RO pretreatment. The expected TOC removal efficiency ranges from 25% to 80%, depending on the nature of the organics. Chlorine can be removed to less than 0.05 ppm. Activated carbon can also be used to remove chloramines in the same manner as chlorine, however, the contact time must be greater than for chlorine removal. For a 12 × 40 mesh carbon, contact times up to 30 min are required. Catalytic activated carbon can also be used to reduce the contact time for chloramine removal.

Carbon filter media tanks are look like multi-media filter tank. We are install sand media for multi-media filter tank and activated carbon for activated carbon filter tank. But some application we can add carbon and sand media in the same time in multi-media filter tank.

Activated activated carbon filter tank are used to reduce the concentration of organics in RO feed water. Activated carbon filter vessels are also used to remove oxidants such as free chlorine from RO feed water. Activated carbon is derived from natural materials such as bituminous coal, lignite, wood, fruit pits, bones, and coconut shells, to name a few. The raw materials are fired in a low oxygen environment to create char, which is then activated by steam, carbon dioxide or oxygen. For most industrial applications, bituminous carbon is used. This is because of the smaller pores size, higher surface area, and higher density than other forms of carbon give bituminous carbon higher capacity for chlorine. Carbon can also come in one of 3 forms: powdered (PAC), extruded block (CB), and granular (GAC). Most industrial applications used GAC as this is the lowest cost of the 3 types of carbon media for activated carbon filter tank and this type of carbon can be reused.

All carbon is characterized by high surface area. A gram of carbon can have surface area in excess of 500m2 , with 1,500m2 being achievable. High surface area is necessary for reduction of organics and chlorine within reasonable contact time in activated carbon filter vessel.

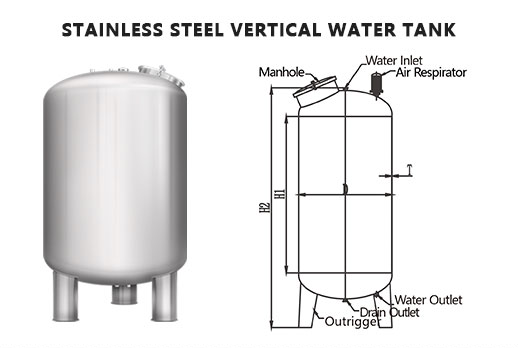

Our activated carbon filter tank materials are FRP, Stainless Steel 304, Stainless Steel 316 and Carbon Steel. Also we can use same material for multi-media filter tank. Our Carbon Steel activated carbon filter vessel outside painted with rust protection chemicals and epoxy paint. Color is optional. Activated carbon filter tank and multi-media filter tank thickness can be design as regards to working pressure.

If water salty like brackish and seawater application we suggest to use FRP or Carbon Steel activated carbon filter vessel.

Our all filter media filter tanks and activated carbon filter tanks optional inlet and outlet flange size.And also our activated carbon filter vessel has 350-400mm main entrance to make cleaning easy.

Product Description

Stainless steel multi media filter housing

Water pretreatment system consists of multi media filter,activated carbon filter,water pump etc.

Material:ss304 or ss316l

Surface:polished,Matt or sand blasting

End cover:dished head with handhold,manhole

Side sight glass

Filter media:quartz sand,Manganese sand,active carbon etc

Design sodium force: 0.6 Mpa

Water distribution method: Brocade tube type, water cap type.

Application: Multi Media Filer, Active Carbon Filter, Softener Deferrizers, Demanganizers.

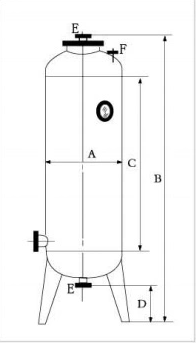

Model | A | B | C | D | Size(E) | Size(F) |

FG-300x1500 | 300 | 2050 | 1500 | 200 | 1” | 3/4” |

FG-350x1500 | 350 | 2050 | 1500 | 200 | 1” | 3/4” |

FG-400x1500 | 400 | 2050 | 1500 | 200 | 1” | 3/4” |

FG-500x1500 | 500 | 2100 | 1500 | 200 | 1 3/4” | 3/4” |

FG-600x1500 | 600 | 2200 | 1500 | 250 | 1 3/4” | 1” |

FG-800x1500 | 800 | 2400 | 1500 | 250 | 1 1/2” | 1” |

FG-900x1500 | 900 | 2500 | 1500 | 250 | 1 1/2” | 1” |

FG-1000x1500 | 1000 | 2500 | 1500 | 250 | 2” | 1” |

FG-1200x1500 | 1200 | 2600 | 1500 | 300 | 2” | 1” |

FG-1400x1500 | 1400 | 2700 | 1500 | 300 | 2” | 1” |

FG-1500x1500 | 1500 | 2800 | 1500 | 300 | 2” | 1” |

FG-1600x1500 | 1600 | 2900 | 1500 | 300 | 3” | 1 3/4” |

FG-1800x1500 | 1800 | 3000 | 1500 | 300 | 3” | 1 3/4” |

FG-2000x1500 | 2000 | 3100 | 1500 | 300 | 4” | 1 3/4” |

FG-2200x1500 | 2200 | 3200 | 1500 | 300 | 4” | 1 3/4” |

FG-2400x1500 | 2400 | 3200 | 1500 | 300 | 4” | 1 1/2” |

FG-2600x1500 | 2600 | 3300 | 1500 | 300 | 5” | 1 1/2” |

FG-2800x1500 | 2800 | 3400 | 1500 | 300 | 6” | 1 1/2” |

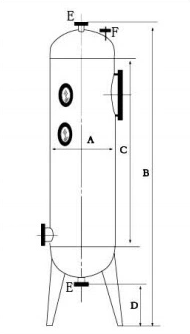

Model | A | B | C | D | Size(E) | Size(F) |

FG-300x2000 | 300 | 2550 | 2000 | 200 | 1” | 3/4” |

FG-350x2000 | 350 | 2550 | 2000 | 200 | 1” | 3/4” |

FG-400x2000 | 400 | 2500 | 2000 | 200 | 1” | 3/4” |

FG-500x2000 | 500 | 2600 | 2000 | 200 | 1 3/4” | 3/4” |

FG-600x2000 | 600 | 2700 | 2000 | 250 | 1 3/4” | 1” |

FG-800x2000 | 800 | 2800 | 2000 | 250 | 1 1/2” | 1” |

FG-900x2000 | 900 | 2900 | 2000 | 250 | 1 1/2” | 1” |

FG-1000x2000 | 1000 | 2900 | 2000 | 250 | 2” | 1” |

FG-1200x2000 | 1200 | 3000 | 2000 | 300 | 2” | 1” |

FG-1400x2000 | 1400 | 3100 | 2000 | 300 | 2” | 1” |

FG-1500x2000 | 1500 | 3250 | 2000 | 300 | 2” | 1” |

FG-1600x2000 | 1600 | 3300 | 2000 | 300 | 3” | 1 3/4” |

FG-1800x2000 | 1800 | 3400 | 2000 | 300 | 3” | 1 3/4” |

FG-2000x2000 | 2000 | 3500 | 2000 | 300 | 4” | 1 3/4” |

FG-2200x2000 | 2200 | 3600 | 2000 | 300 | 4” | 1 3/4” |

FG-2400x1500 | 2400 | 3200 | 2000 | 300 | 4” | 1 1/2” |

FG-2600x1500 | 2600 | 3300 | 2000 | 300 | 5” | 1 1/2” |

FG-2800x1500 | 2800 | 3400 | 2000 | 300 | 6” | 1 1/2” |