Ultrafiltration Membrane for Tertiary Wastewater Treatment

Ultrafiltration (UF) membranes are an essential component in advanced tertiary wastewater treatment, offering a reliable and efficient solution to purify water after the primary and secondary treatment processes. By utilizing UF membranes, water treatment plants can remove suspended solids, microorganisms, and large particles, ensuring that the treated water meets high standards for reuse and environmental protection. With their fine filtration capabilities, UF membranes play a key role in producing high-quality effluent for industrial, municipal, and agricultural applications.

Product Overview:

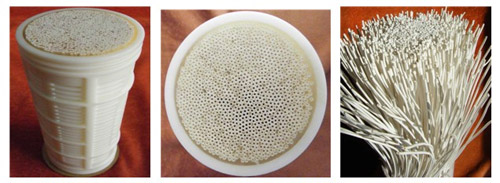

The Ultrafiltration Membrane is a semi-permeable membrane designed to filter out particles ranging from 0.01 to 0.1 microns in size. This allows for the removal of larger particles, bacteria, viruses, and colloidal substances, while allowing clean water to pass through. UF membranes are commonly used as part of tertiary treatment systems to improve the quality of effluent before it is discharged into natural bodies of water or recycled for industrial processes, irrigation, or even potable water production.

The Ultrafiltration Membrane is often selected for its high efficiency, durability, and the ability to provide consistent filtration without the need for chemicals. Its compact design and ease of installation make it suitable for a variety of wastewater treatment applications across industries.

Uses:

Municipal Wastewater Treatment: UF membranes are widely used in municipal treatment plants to provide high-quality effluent that meets stringent environmental regulations for discharge or reuse.

Industrial Wastewater Treatment: Industries, including food and beverage, pharmaceuticals, and chemicals, rely on UF membranes to treat wastewater and reuse water within their operations.

Agricultural Water Reuse: In agricultural settings, UF membranes are used to treat wastewater for irrigation, ensuring that water used for crops is free of contaminants.

Potable Water Production: In some cases, UF membranes are part of a multi-stage treatment process to produce potable water from wastewater sources.

Desalination Pretreatment: UF membranes are often used as pretreatment in reverse osmosis systems for desalination, as they efficiently remove larger particles before the water undergoes further filtration.

Specifications:

| Feature | Details |

|---|

| Filtration Size | 0.01 to 0.1 microns |

| Membrane Type | Hollow fiber, flat sheet, or spiral wound |

| Flux Rate | 25-60 LMH (liters per square meter per hour) |

| Material | Polymeric (PVC, PVDF, PES) |

| Operating Pressure | 1-2 bar (14-29 psi) |

| Temperature Range | 5°C to 45°C |

| Capacity | Customized based on wastewater flow rate |

| Service Life | Typically 3-7 years, depending on conditions |

Advantages:

Efficient Filtration: UF membranes provide effective removal of suspended solids, bacteria, and other contaminants from wastewater.

Low Energy Consumption: Unlike other filtration methods, UF requires relatively low energy, making it a cost-effective option for long-term operation.

No Need for Chemicals: UF membranes can operate without chemicals, reducing the need for additional treatment chemicals and making it environmentally friendly.

Compact Design: The membranes are space-efficient, allowing for easy integration into existing wastewater treatment systems.

High Flux Rate: With high water flux rates, UF membranes ensure efficient and continuous filtration, reducing the frequency of cleaning and maintenance.

Long Service Life: With proper maintenance, UF membranes can last several years, providing a durable solution for wastewater treatment.

Frequently Asked Questions (FAQ):

What is ultrafiltration used for in wastewater treatment?

Ultrafiltration is used to remove suspended solids, bacteria, viruses, and other contaminants from wastewater in tertiary treatment, ensuring high-quality effluent for reuse or discharge.

How long do UF membranes last?

Do UF membranes require chemicals for operation?

Can ultrafiltration be used for drinking water production?

How do I maintain ultrafiltration membranes?

Routine cleaning and monitoring are essential to maintain the performance of UF membranes. Cleaning protocols typically include backwashing, chemical cleaning, and regular monitoring of flow rates and pressure.

After-Sales Support:

We provide comprehensive after-sales support for all our Ultrafiltration Membrane products. This includes installation guidance, operational training, and ongoing maintenance services to ensure optimal performance. Our technical support team is available to assist with troubleshooting, membrane replacement, and customized cleaning solutions to extend the life of your system. Additionally, we offer a warranty period and post-installation service to ensure that your investment in ultrafiltration technology continues to provide high-quality effluent treatment.

Conclusion:

The Ultrafiltration Membrane is a reliable and efficient solution for tertiary wastewater treatment. Its ability to provide high-quality effluent with low energy consumption and no need for chemicals makes it a cost-effective, sustainable choice for municipal, industrial, and agricultural applications. By selecting ultrafiltration technology, you can ensure that your wastewater treatment process meets stringent regulatory standards while offering the flexibility and durability required for long-term success.