DOW™ SFP-2860 And SFD-2860 Ultrafiltration Module(UF Ultrafiltration Membrane 51m2)

DOW™ ultrafiltration (UF) modules are made of high-strength hollow fiber membranes that offer outstanding features and benefits:

• Nominal pore size of 0.03 µm removes bacteria, viruses, and particulates including colloids to protect downstream processes such as reverse osmosis.

• Polyvinylidene fluoride (PVDF) polymer hollow fibers provide high strength and chemical resistance to extend membrane life.

• Hydrophilic PVDF fibers are easy to clean and wet, helping to maintain long-term performance.

• Outside-in flow configuration provides high tolerance to feed solids, helping to reduce the need for pre-treatment processes.

• U-PVC housing helps eliminate the need for expensive pressure vessels.

This module is ideal for systems with capacities greater than 50 m3/hr (220 gpm). The larger 8-inch diameter module offers the highest active membrane area of any DOW UF module, helping to achieve more economical membrane system design. The shorter 60-inch length modules offer higher efficiency over a wider range of influent conditions than longer modules.

DOWTM UF modules can be used in a variety of treatment applications such as surface water, seawater, industrial wastewater and secondary effluent wastewater.

Product Specifications

Membrane area | Module volume | Weight (empty/ water filled) |

Model | Type | Part # | m2 | ft2 | Liters | Gallons | Kg | lbs |

SFP-2860 | Pretreatment | 280933 | 51 | 549 | 35 | 9.3 | 48/83 | 106/183 |

SFD-2860 | NSF/ANSI 61 Drinking water | 324168 | 51 | 549 | 35 | 9.3 | 48/83 | 106/183 |

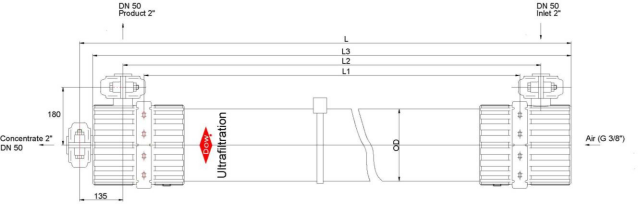

Figure 1: SFP and SFD 2860 (8-inch diameter)

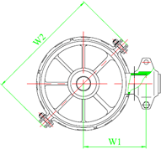

Figure 2

Properties |

| Length |

|

| Diameter | Width |

|

Units | L | L1 | L2 | L3 | D | W1 | W2 |

SI (mm) | 1860 | 1500 | 1630 | 1820 | 225 | 180 | 342 |

Operating Parameters

| SI units | US units |

Filtrate Flux @ 25ºC | 40-120 l/m2/ hr | 24-70 gfd |

Flow range | 2.0 – 6.1 m3/hr | 9.2 – 26.7 gpm |

Temperature | 1-40ºC | 34-104ºF |

Max. inlet module pressure (@ 20ºC) | 6.25 bar | 93.75 psi |

Max. operating TMP | 2.1 bar | 30 psi |

Max operating air scour flow | 12 nm3/hr | 7.1 scfm |

Max backwash pressure | 2.5 bar | 36 psi |

Operating pH | 2- 11 |

NaOCl (max.) | 2,000 mg/L |

TSS (max.) | 100 mg/L |

Turbidity (max.) | 300 ntu |

Particle size (max.) | 300 µ |

Flow configuration | Outside in, dead end flow |

Expected filtrate turbidity | ≤0.1 NTU |

Expected filtrate SDI | ≤2.5 |

Important information

Proper start-up of a UF system is indispensable for preparing the membranes for operational service and preventing membrane damage. Adhering to the correct start-up sequence also contributes to ensuring that the operating parameters of the system conform to the design specifications, thereby enabling the attainment of system water quality and productivity targets. Before commencing the system start-up procedures, membrane pretreatment, installation of the membrane modules, instrument calibration, and other system checks should be accomplished. Kindly refer to the product technical manual.

Operation guidelines

Avoid any sudden pressure fluctuations during start-up, shutdown, cleaning or other processes to prevent potential membrane damage. Flush the UF system to eliminate the shipping solution before start-up. Remove the residual air from the system before start-up. Manually initiate the equipment. Aim for a permeate flow of 60% of the design during the initial operations. Depending on the application, the permeate obtained from the initial operations should be disposed of. Please refer to the product technical manual.

Regulatory note

NOTICE: NSF/ANSI 61 certified drinking water modules demand specific conditioning procedures before generating potable water. Please refer to the flushing section of the product technical manual for detailed procedures. Drinking water modules might be subject to additional regulatory constraints in certain countries. Please verify local regulatory guidelines and the application status before usage and sale.

The utilization of this product does not inevitably ensure the elimination of cysts and pathogens from water. Effective reduction of cysts and pathogens depends on the complete system design as well as the operation and maintenance of the system.

Notice: No inference should be made regarding the absence of infringement of any patent owned by Dow or others. As the use conditions and applicable laws may vary from one location to another and may change over time, the Customer is accountable for determining whether the products and the information in this document are suitable for the Customer's use and for ensuring that the Customer's workplace and disposal practices comply with applicable laws and other governmental enactments. The product presented in this literature might not be available for sale and/or available in all geographical areas where Dow is represented. The claims made might not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to "Dow" or the "Company" signify the Dow legal entity selling the products to the Customer unless otherwise explicitly noted. NO WARRANTIES ARE PROVIDED; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED.

For detailed parameters, please visit:

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.