DOW™ FILMTEC SFD-2660 ultrafiltration membrane Meets NSF/ANSI 61 Drinking Water Standards uf membrane filter

The SFD series of DOW ultrafiltration modules, constructed with robust outside-in PVDF fiber technology, are highly suited for drinking water applications. These modules boast hollow fibers that offer exceptional cleanability, reduced chemical consumption, high recovery rates, and an unmatched blend of mechanical properties and chemical resistance.

Specifically, the DOW ultrafiltration SFD-2660 is an excellent choice for smaller systems, enabling a compact design while maintaining performance. It is certified by NSF/ANSI Standard 61, ensuring its safe and reliable use in drinking water applications.

Advantages of the DOW Ultrafiltration Modules:

* Excellent removal of colloids, particles, and bacteria, ensuring high-quality drinking water.

* Low chemical consumption, reducing operational costs and environmental impact.

* Ability to effectively treat challenging feed water, even with limited pretreatment, for a more efficient process.

* High chemical-tolerant PVDF material, allowing for aggressive chemical use when needed to tackle particularly difficult water qualities.

* Mechanically strong fibers ensure a long module lifespan, providing reliable performance over extended periods.

Important Information Regarding UF System Start-Up:

Proper start-up of a UF system is crucial for preparing the membranes for operational service and preventing any damage. Adhering to the correct start-up sequence is essential to ensure that the system's operating parameters align with the design specifications, allowing for the achievement of water quality and productivity goals. Prior to commencing the start-up procedures, it is vital to complete the membrane pretreatment, installation of membrane modules, instrument calibration, and conduct other system checks. For detailed instructions and guidelines, please refer to the product technical manual.

Operation Guidelines for UF System:

During start-up, shutdown, cleaning, or any other operational sequences, it is crucial to avoid any abrupt pressure variations to prevent potential membrane damage. Before commencing operation, ensure to flush the UF system thoroughly to remove any shipping solution residue. Additionally, remove any residual air from the system to prevent any operational issues.

Manually start the equipment and initially target a permeate flow rate of approximately 60% of the design flow rate. Depending on the specific application, it may be necessary to discard the permeate obtained during initial operations.

For detailed operational instructions, including recommended flow rates, cleaning procedures, and troubleshooting guidelines, please refer to the product technical manual. Adhering to these guidelines will ensure optimal performance and longevity of the UF system.

FEATURES of DOW™ Ultrafiltration (UF) Modules

The DOW™ ultrafiltration (UF) modules are crafted from hollow fiber membranes of superior strength, boasting numerous outstanding features and benefits:

1. **Nominal Pore Diameter of 0.03µm**: Effectively removes bacteria, viruses, and various particulates, including colloids, safeguarding downstream processes like reverse osmosis (RO).

2. **PVDF Polymeric Hollow Fibers**: Their high strength and chemical resistance contribute to a longer membrane lifespan, ensuring reliable performance over extended periods.

3. **Hydrophilic PVDF Fibers**: Facilitate easy cleaning and ensure excellent wettability, crucial for maintaining long-term performance and operational efficiency.

4. **Outside-In Flow Configuration**: This design exhibits high tolerance to feed solids, minimizing the need for costly and complex pretreatment processes.

5. **U-PVC Housing**: Cost-effective and durable, it helps eliminate the requirement for expensive pressure vessels, further reducing overall operational costs.

Collectively, these features enable the DOW™ UF modules to deliver superior performance in a range of water treatment applications, ensuring both efficiency and reliability.

For application cases, please click:https://www.fgwater.com/Industries/

APPLICATIONS OF DOW™ Ultrafiltration (UF) Modules

The DOW™ ultrafiltration (UF) modules are versatile and suitable for a wide range of water treatment applications, including:

1. **Groundwater and Surface Water Treatment**: Effectively removes impurities, bacteria, and viruses from groundwater and surface water sources, ensuring safe and reliable drinking water supply.

2. **Seawater Desalination Pretreatment**: Plays a crucial role in the pretreatment process of seawater desalination, removing particulate matter and other contaminants that can foul or damage desalination membranes.

3. **Wastewater Treatment**: Assists in the treatment of industrial and municipal wastewater, reducing pollutants and contaminants before discharge or reuse.

4. **Municipal Drinking Water Systems**: Enhances the quality of drinking water in municipal systems by removing suspended solids, bacteria, and viruses, improving water clarity and taste.

5. **Containerized Systems**: Ideal for mobile or temporary water treatment facilities, these UF modules can be easily integrated into containerized systems for quick deployment and operational flexibility.

Whether it's for residential, industrial, or municipal use, the DOW™ UF modules provide reliable performance and ensure water quality standards are met in various water treatment scenarios.

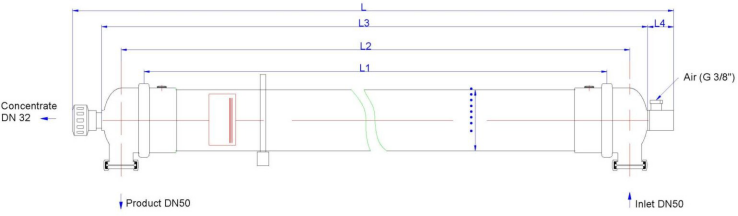

Figure 1: SFP and SFD 2660 (6-inch diameter)

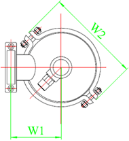

Figure 2

Properties |

| Length |

|

| Diameter | Width |

|

Units | L | L1 | L2 | L3 | D | W1 | W2 |

SI (mm) | 1860 | 1500 | 1610 | 1710 | 165 | 125 | 250 |

For detailed parameters, please visit:

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.