Application Cases of SFP-2860 Ultrafiltration Membrane Technology in Water Treatment of Environmental Engineering in Southeast Asian Countries

Introduction

With the rapid economic development and population growth in Southeast Asia, water pollution is becoming increasingly serious. In order to improve the quality of water environment and protect people's health, many Southeast Asian countries have begun to turn their attention to advanced water treatment technologies. Among them, ultrafiltration membrane technology has received widespread attention due to its high efficiency, energy saving, and environmental protection. As a new type of ultrafiltration membrane material, SFP-2860 has shown great potential in water treatment projects in Southeast Asia.

Introduction to SFP-2860 Ultrafiltration Membrane Technology

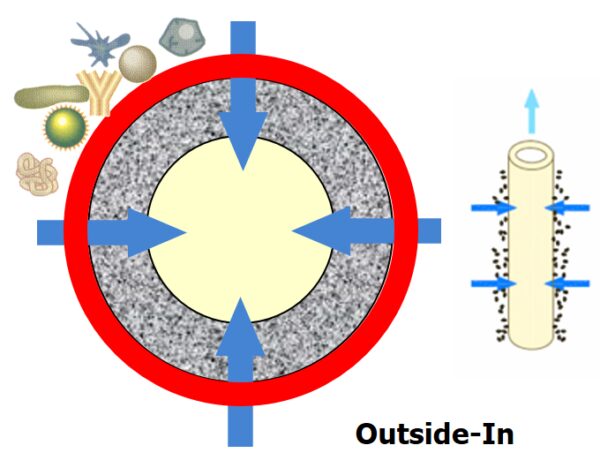

SFP-2860 ultrafiltration membrane is a polysulfone-based composite membrane with excellent performance, which has the characteristics of high flux, high retention rate, chemical corrosion resistance, and pollution resistance. Its pore size distribution is uniform, which can effectively intercept impurities such as suspended matter, colloids, bacteria, and viruses in water, while allowing water molecules and small solutes to pass freely.

Application Case Analysis

1. Industrial Wastewater Treatment in Thailand

Problem: The wastewater discharged by many industrial enterprises in Thailand contains a large amount of organic matter, heavy metals and suspended solids, which seriously pollutes the water environment.

Solution: Use SFP-2860 ultrafiltration membrane to deeply treat industrial wastewater, effectively remove suspended matter, colloids and some organic matter, reduce COD and BOD indicators, and meet emission standards.

Advantages: SFP-2860 membrane has good acid and alkali resistance and organic solvent resistance, can adapt to complex industrial wastewater quality, and has high flux, reducing operating costs.

2. Drinking Water Treatment in Vietnam

Problem: Groundwater and surface water in some parts of Vietnam are polluted, and direct drinking poses health risks.

Solution: Apply SFP-2860 ultrafiltration membrane to drinking water treatment process to remove microorganisms such as bacteria, viruses, algae, and impurities such as suspended matter and colloids in water to ensure the safety and hygiene of drinking water.

Advantages: The SFP-2860 membrane has a high retention rate and can effectively remove pathogenic microorganisms in the water without introducing additional chemicals, ensuring the purity of the effluent.

3. Municipal sewage treatment in Indonesia

Problem: Indonesia's urbanization process is accelerating, and the urban sewage treatment capacity is insufficient, posing a serious threat to the water environment.

Solution: Introduce the SFP-2860 ultrafiltration membrane process in the municipal sewage treatment plant to deeply treat the sewage after biochemical treatment, remove the remaining suspended matter, bacteria and viruses, improve the effluent water quality, and realize sewage reuse.

Advantages: The SFP-2860 membrane has high pollution resistance and can adapt to the complexity of municipal sewage. It also has a long service life and reduces maintenance costs.

Application prospects of SFP-2860 ultrafiltration membrane technology in Southeast Asia

SFP-2860 ultrafiltration membrane technology has broad application prospects in the field of water treatment in Southeast Asian countries. With the continuous maturity of technology and the reduction of costs, the SFP-2860 membrane will play a greater role in the following aspects:

Improve water environment quality: Effectively remove pollutants in water and protect water resources.

Improve water resource utilization: Realize wastewater reuse and alleviate water shortage.

Promote economic development: Provide high-quality water sources for industrial production and promote economic development.

Conclusion

As an efficient and environmentally friendly water treatment technology, SFP-2860 ultrafiltration membrane technology has shown great potential in water treatment projects in Southeast Asian countries. Through the analysis of different application cases, it can be seen that SFP-2860 membrane plays an important role in improving water quality and protecting the environment. With the continuous advancement and promotion of technology, SFP-2860 membrane will be more widely used in the field of water treatment in Southeast Asia

For application cases, please click:https://www.fgwater.com/Industries/

Power generation: Producing high-purity water for boilers and cooling towers.

Semiconductor manufacturing: Providing ultrapure water for wafer fabrication processes.

Pharmaceutical industry: Manufacturing pharmaceutical-grade water for drug production.

Food and beverage industry: Producing purified water for beverages, processed foods, and cleaning equipment.

Chemical processing: Creating high-purity water for chemical reactions and product rinsing.

Desalination: Converting seawater or brackish water into potable water.

Advantages of RO Systems

High rejection rates: RO systems can effectively remove a wide range of contaminants, including dissolved salts, organic compounds, and microorganisms.

Energy efficiency: While pressure is required to drive the process, advances in membrane technology have led to more energy-efficient systems.

Compact design: RO systems can be designed to fit into various spaces, making them suitable for a wide range of applications.

Low maintenance: With proper pretreatment, RO systems require minimal maintenance.

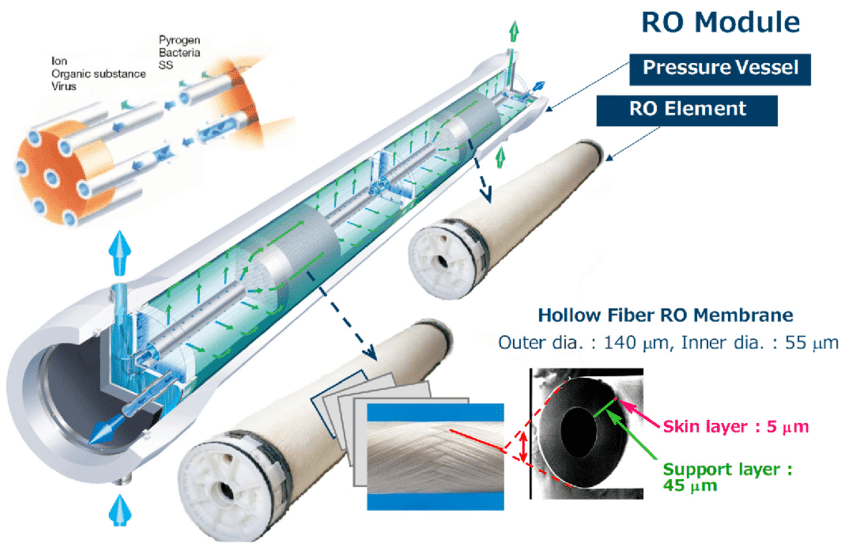

Types of RO Membranes

The performance of an RO system is largely dependent on the type of membrane used. Common types of RO membranes include:

Cellulose acetate: These membranes have been used for many years but are susceptible to fouling and have lower rejection rates compared to newer materials.

Thin-film composite (TFC): TFC membranes offer higher rejection rates, better chemical resistance, and lower fouling tendencies than cellulose acetate membranes. They are the most widely used RO membranes today.

Polyamide: Polyamide membranes are a type of TFC membrane that is known for its excellent performance and durability.

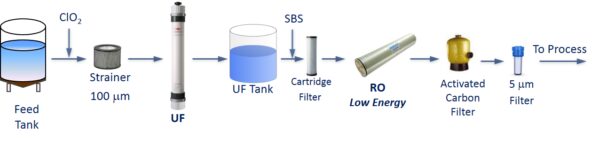

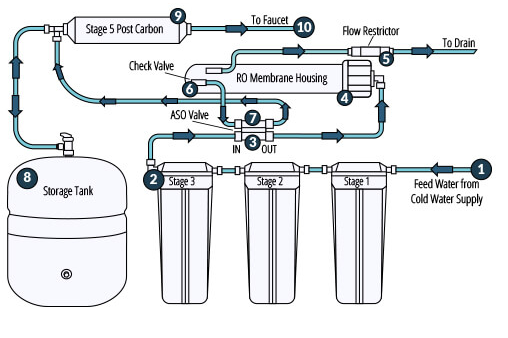

Components of an RO System

A typical industrial RO system consists of the following components:

Pre-treatment: This stage involves removing suspended solids, chlorine, and other contaminants that could damage the RO membrane.

High-pressure pumps: These pumps provide the necessary pressure to force water through the RO membrane.

RO membrane elements: The heart of the system, where the actual separation of water and impurities occurs.

Post-treatment: Depending on the application, post-treatment may be required to further purify the permeate or adjust its pH or conductivity.

Our RO systems include:

SWRO - Seawater Reverse Osmosis System: https://www.fgwater.com/SWRO-Seawater-Reverse-Osmosis-System/

BWRO - Brackish Water Reverse Osmosis System: https://www.fgwater.com/BWRO-Brackish-Water-Reverse-Osmosis-System/

In addition to RO systems, we also have:

EDI: https://www.fgwater.com/Electrodeionization-EDI-Stack-Module/

Ultrafiltration membrane: https://www.fgwater.com/Dupont-Ultrafiltration-Membrane-Module/

For other water treatment products, please click: https://www.fgwater.com/PRODUCTS/

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.