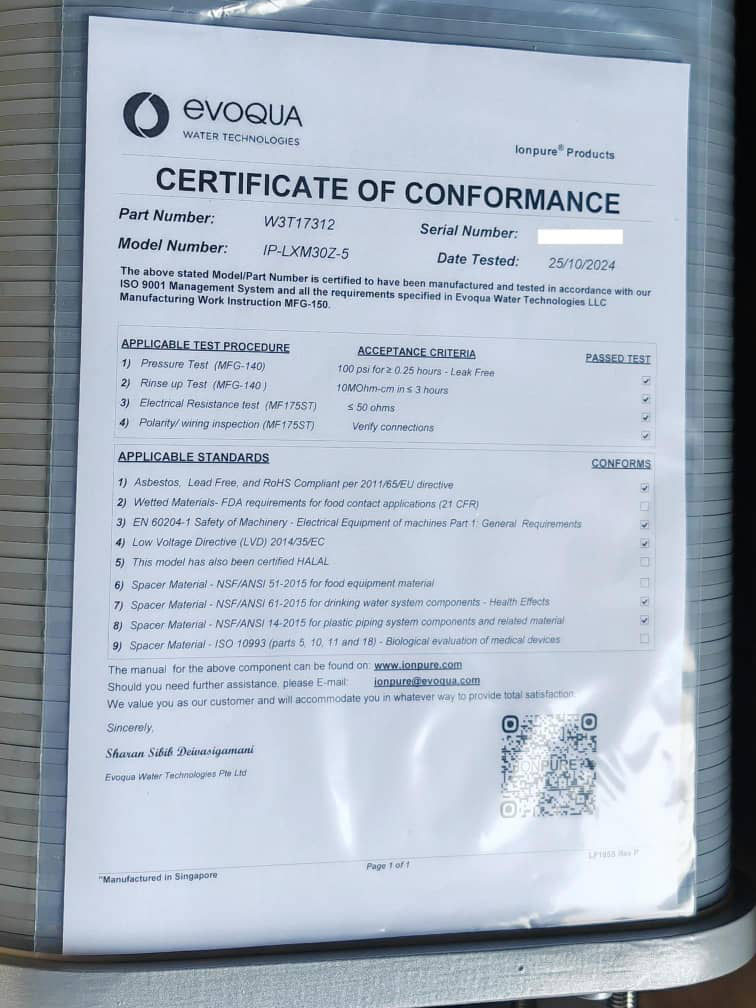

IONPURE® IP-LXM30Z-5 CEDI Modules

IONPURE LX-Z — INDUSTRIAL CEDI MODULE

The Ionpure LX-Z-5 modules with improved chlorine tolerance are specifically designed for a wide range of industrial deionized water applications and markets, including boiler makeup water for power plants, pharmaceutical pure water, water for hydrocarbon and chemical processing (HPI/CPI) and other high purity needs.

IONPURE CEDI modules provide a constant flow of high purity water without the need for downtime or chemical regeneration like conventional deionization methods.

LX-Z Series Features

• Significantly lower operating costs than conventional ion exchange

• Generates mixed-bed quality deionized water without the use of chemicals

• Continuous production instead of batch, with consistent quality

• Double O-ring seal guarantees leak-free operation

• No need for acid/caustic, neutralization system or exchangeable DI tanks

• Resin filled concentrate for optimal performance and ease of operation

• Continuous operation

• Up to 0.05 ppm (total CI2) feed

• Wide range of flow from 0.22 m3/h (1 gpm) to 7.67 m3/h (33.8 gpm) per module

• Wetted materials of construction comply with NSF® 14 and NSF® 61 requirements

IP-LXM30Z-5 Typical Applications

l Semiconductor Manufacturing

Final polishing for UPW systems, achieving TOC <0.5 ppb for wafer cleaning and etching processes.

l Photovoltaics

Integrated with RO+EDI systems for silicon wafer cutting/cleaning, delivering stable resistivity >17 MΩ·cm.

l Chemical & Power Industries

Replaces traditional mixed-bed DI in boiler feedwater systems, reducing chemical waste costs.

IP-LXM30Z-5 Data sheet

Product Flow Min. GPM (m3/hr) | 7.5 (1.65) |

Product Flow Nominal GPM (m3/hr) | 15.0 (3.3) |

Product Flow Max. GPM (m3/hr) | 22.5 (5.1) |

Recovery | 90-95% |

DC Voltage | 0-400 |

DC Amperage | 1.0-6.0 |

Product Resistivity | Minimum Flow > 17 MΩ-cm*† Maximum Flow > 7 MΩ-cm*† |

Silica (SiO2) Removal | 90–99%, depending on feed conditions |

Feed Water Conductivity Equivalent, including CO2 and Silica | < 40 μS/cm |

Feed Water Source | RO permeate |

Temperature | 5–45˚C (41–113˚F) |

Inlet Pressure | 1.4–6.9 bar (20–100 psig) |

Maximum Total Chlorine (as Cl2) | < 0.05 ppm |

Iron (as Fe) | < 0.01 ppm |

Manganese (as Mn) | < 0.01 ppm |

Sulfide (S2-) | < 0.01 ppm |

pH | 4–11 |

Total Hardness (as CaCO3) | < 1.0 ppm |

Dissolved Organics (TOC as C) | < 0.5 ppm |

Silica (SiO2) | < 1.0 ppm |

Reference pictures:

For more products, please click: https://www.fgwater.com/Evoqua-Electrodeionization-EDI-Stack-Module/