Ultrafiltration (UF) Technology

Achieve High-Quality Water with Pressure-Driven Purification

Ultrafiltration (UF) is an advanced water purification process that utilizes an ultrafine membrane to separate particulate matter from soluble compounds. UF is especially effective as a pretreatment for desalination, reverse osmosis (RO), and wastewater reclamation, offering reliable, high-quality potable water.

What is Ultrafiltration (UF)?

Ultrafiltration (UF) uses a membrane barrier with pore sizes between 0.02 to 0.05 microns, which allows it to exclude particles such as bacteria, viruses, colloids, and macromolecules, meeting stringent water-quality standards globally.

Why Choose UF Over Traditional Filtration?

| Traditional Filtration (e.g., Sand Filters) | Ultrafiltration (UF) |

|---|

| Removes particles down to ~5 microns. | Removes particles, bacteria, and viruses down to 0.02-0.05 microns. |

| Dependent on consistent raw water quality. | Tolerates feedwater quality upsets. |

| Requires pretreatment chemicals (polymer, coagulants). | No pretreatment chemicals required. |

| Larger footprint and higher weight. | Smaller footprint, lighter, and more efficient. |

Advantages of UF:

High and Consistent Product Quality: Measured by turbidity (NTU) or silt density index (SDI).

Tolerance to Feedwater Quality Upsets: Robust against water quality fluctuations.

No Need for Pretreatment Chemicals: Lower operational costs and no sludge disposal.

Compact and Lightweight: Requires less space compared to traditional media filters.

UF in Reverse Osmosis (RO) Pretreatment

When used as a pretreatment for reverse osmosis (RO), UF membranes help minimize RO membrane fouling, leading to:

Reduced Chemical Cleaning: Lower maintenance and operating costs.

Lower Capital Costs for RO Systems: Fewer membranes and vessels required.

Higher Flux: Potential for faster processing with less downtime.

UF Technology Basics:

UF operates by applying pressure to drive water through a membrane, leaving larger particles, colloids, and bacteria behind. The membrane pores range from 0.02 to 0.05 microns, ensuring that harmful microorganisms are filtered out, but smaller particles like dissolved salts and organics pass through.

Key UF Performance Features:

Pressure: Feed pressure typically < 30 psig, transmembrane pressure < 14 psig.

Membrane Pore Size: 0.02 – 0.05 microns.

Service Life: 3 to 7 years, with proper maintenance.

Hollow Fiber Ultrafiltration Technology:

Our UF modules use hollow-fiber membranes made from high-strength PVDF (Polyvinylidene Fluoride), ensuring excellent performance and longevity.

Key Features:

Nominal Pore Diameter: 0.03 μm for high bacteria, virus, and particulate removal.

Material: PVDF for chemical resistance and durability.

Hydrophilic Properties: Easy cleaning and long-term performance.

Outside-In Flow Configuration: Allows for high tolerance to feed solids and easy air scour cleaning.

Performance Benefits:

Why Choose DuPont™ IntegraTec™ Ultrafiltration Solutions?

Proven Expertise: Deep capabilities and advanced knowledge in membrane technology.

Customer-Centric: We are dedicated to your success and offer a one-stop solution.

Reliable Performance: Long-lasting modules and rack configurations to meet diverse needs.

World-Class Manufacturing: We provide high-quality UF solutions with proven durability.

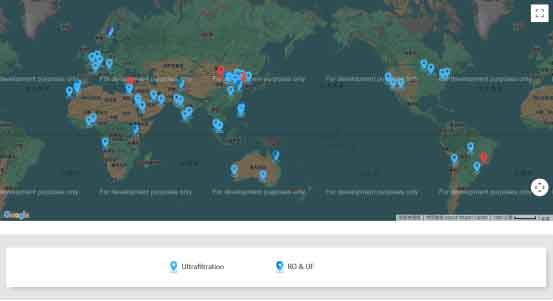

Selected UF references around the globe

Contact Information: