Veolia EDI E-Cell Stack MK-9 System Revolutionizing Demineralization for Industrial Use

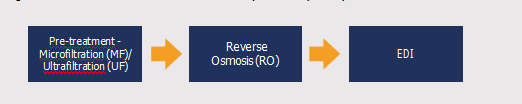

For years, operators of pure water production systems sought a more efficient technology to replace the traditional mixed bed ion exchange for final demineralization. The high operating costs and the complexities associated with acid and caustic regeneration were major pain points. EDI technology has emerged as the ideal solution, offering a reduction in operating costs, a safer environmental and health profile, and the ability to provide a continuous and steady supply of high-purity water.

The production of pure water has evolved significantly, moving from conventional ion exchange systems to membrane-based technologies like EDI, which are now considered best practice by industry leaders worldwide.

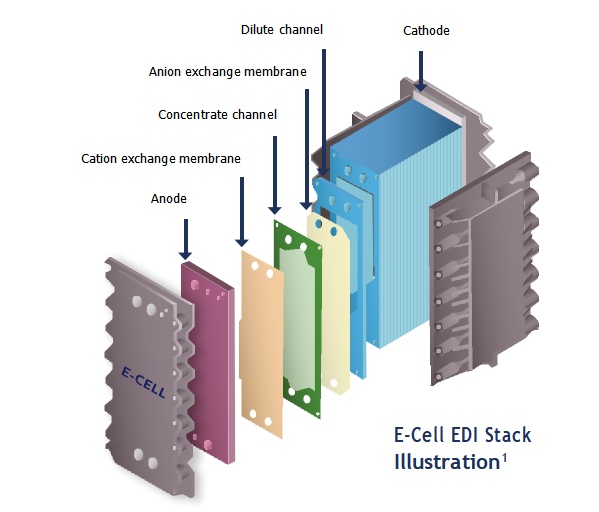

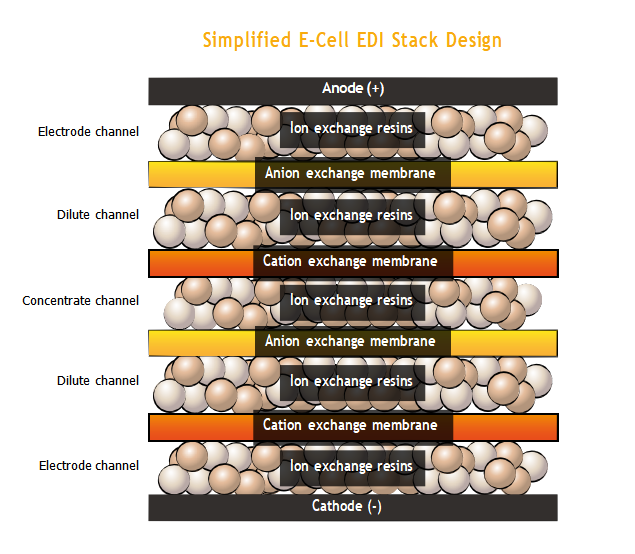

How EDI Works

EDI combines traditional ion exchange resin with ion exchange membranes to remove both charged and uncharged contaminants (such as silica and boron). The technology employs direct current to drive contaminants from the feed water through the ion exchange membranes into the concentrate channels. This current also splits water into hydrogen and hydroxyl ions, acting as continuous regenerating agents. This eliminates the need for chemical regeneration, allowing for a continuous and predictable production of high-purity water.

Advantages of EDI Over Mixed Bed Ion Exchange

Advanced Technology: Utilizing direct current and ion exchange membranes.

No Chemicals: No regeneration chemicals or neutralization systems are required.

Lower Operating Costs: Significant reduction in operating and maintenance costs.

Continuous Operation: Simplified design for uninterrupted operation.

Smaller Footprint: Reduced building height and space requirements.

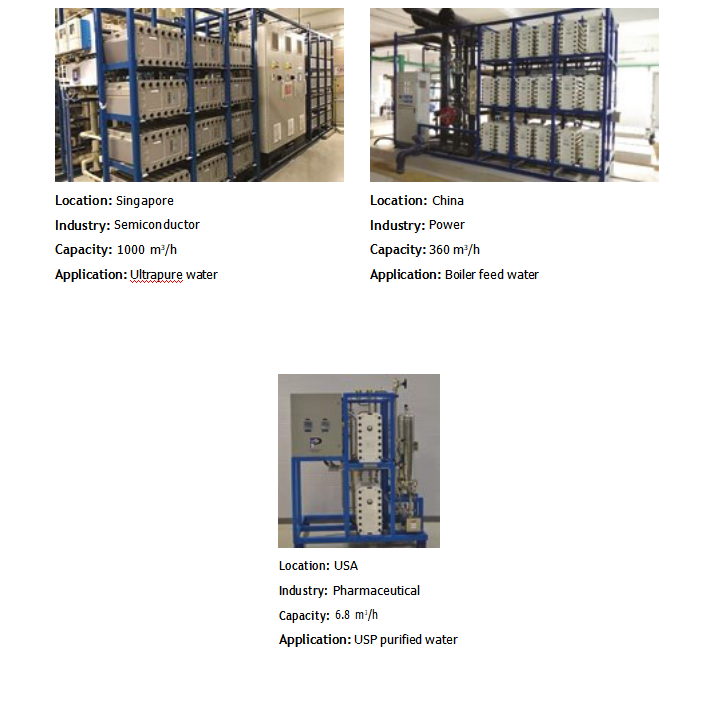

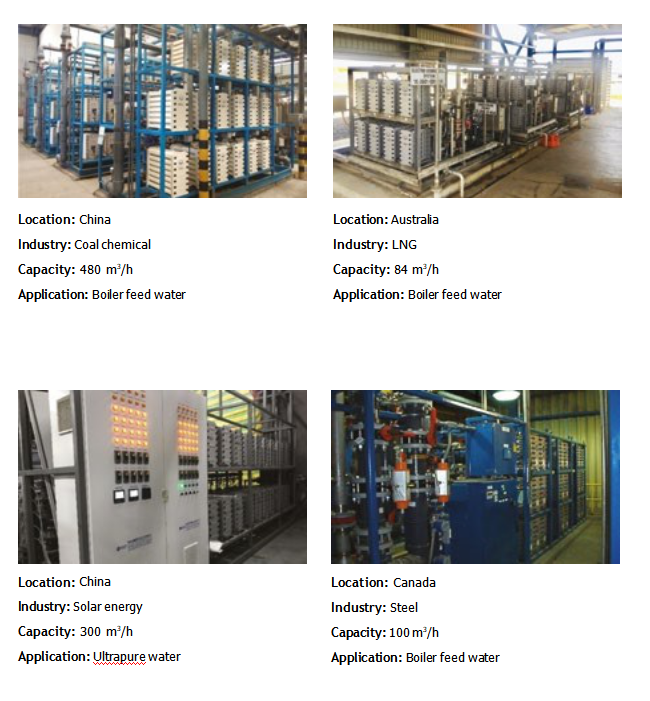

Typical EDI Applications

Semiconductor and Microelectronics: High-purity water for production and rinsing.

Pharmaceutical: Water purification for various industry applications.

Power Generation: Boiler feed water in chemical, steel, and metallurgical industries.

Laboratory: Critical water for research and analytical purposes.

F-Cell EDI Stacks: Next-Generation Performance

Veolia’s E-Cell EDI stacks provide leading product water quality, low energy consumption, and exceptional reliability. With modular stack-and-rack designs, these stacks adapt to varying project requirements and can be tailored to suit any application. Veolia is committed to offering performance guarantees, ensuring superior water quality.

E-Cell EDI Stack Features

Low Energy Consumption: Minimizes operating costs and environmental impact.

Reliable Performance: Known for dependable operation in demanding applications.

Counter-Current Operation: Reduces scale formation, enhancing stack longevity.

Simplified System Design: No need for degassing, recirculation loops, or added salts.

Quality Assurance

Certified Manufacturing: ISO 9001 and ISO 14001 compliant.

Pharmaceutical-Grade: FDA compliant (pharmaceutical modules).

Certified Halal: Manufactured according to IFANCA standards.

E-Cell EDI Stack Specifications

| Stack Model | MK-9 | MK-5 | MK-3 |

|---|

| Shipping Weight (kg) | 165 | 165 | 100 |

| Dimensions (cm) | 30 x 61 x 74 | 30 x 61 x 72 | 30 x 61 x 54 |

| Feed Water Quality |

|

|

|

| Total Exchangeable Anions (ppm as CaCO3) | < 13 | < 25 | < 25 |

| Conductivity (μS/cm) | < 22 | < 43 | < 43 |

| pH | 4-11 | 4-11 | 4-11 |

| Temperature (°C) | 4.4-40 | 4.4-40 | 4.4-40 |

| Hardness (ppm as CaCO3) | < 1.0 | < 1.0 | < 1.0 |

| Silica (ppm as SiO2) | < 1.0 | < 1.0 | < 1.0 |

| TOC (ppm) | < 0.5 | < 0.5 | < 0.5 |

| Turbidity (NTU) | < 1.0 | < 1.0 | < 1.0 |

| Chlorine (ppm) | < 0.05 | < 0.05 | < 0.05 |

| Fe, Mn, H2S (ppm) | < 0.01 | < 0.01 | < 0.01 |

| Product Water Quality |

|

|

|

| Resistivity (MΩ·cm) | > 16 | > 16 | > 16 |

| Silica Removal (SiO2) | Up to 99% / < 5 ppb | Up to 99% / < 5 ppb | Up to 99% / < 5 ppb |

| Operating Parameters |

|

|

|

| Max Water Production (m3/hr) | 10 | 6.4 | 4.5 |

| Min Water Production (m3/hr) | 4.2 | 2.3 | 1.6 |

| Recovery | Up to 97% | Up to 97% | Up to 96% |

| Voltage (VDC) | 0-400 | 0-400 | 0-300 |

| Amperage (ADC) | 0-5.2 | 0-5.2 | 0-5.2 |

| Inlet Pressure (bar) | 4.1-6.9 | 4.1-6.9 | 4.1-6.9 |

| Hot Water Sanitizable Stacks |

|

|

|

| Max Sanitization Temp (°C) | 85 | 85 |

|

| Number of Sanitization Cycles | 160 | 160 |

|

New Model Launch

The E-Cell MK-9, MK-5, and MK-3 models replace the older MK-3 stack, offering enhanced features and performance improvements. For more details, visit the Veolia E-Cell EDI Stack product page.

Contact Us

For inquiries or to make a purchase, please contact us via email at [email protected]. Alternatively, visit our Contact Us page for more details.