DOW™ Ultrafiltration Modules Model SFP-2860, SFD 2860, SFP-2880 and SFD-2880

DOW Ultrafiltration (UF) modules are crafted from PVDF hollow fiber membranes of high mechanical strength. These modules offer outstanding performance and industry-leading membrane area. They possess the following properties and characteristics:

Ultrafiltration (UF) modules are crafted from PVDF hollow fiber membranes of high mechanical strength. These modules offer outstanding performance and industry-leading membrane area. They possess the following properties and characteristics:

• A 0.03 µm nominal pore diameter for the removal of bacteria, viruses, and particulates, including colloids, to safeguard downstream processes such as RO.

• PVDF polymeric hollow fibers provide high mechanical strength and chemical resistance, ensuring a long membrane life and reliable operation.

• Hydrophilic PVDF fibers facilitate easy cleaning and wettability, aiding in maintaining long-term performance.

• The Outside-In flow configuration enables a wide range of solids in the feed water, minimizing the need for pretreatment processes and reducing the backwash volume compared to Inside-Out configurations. U-PVC housing helps eliminate the need for costly pressure vessels.

The 2860, which is shorter in length, is recommended for smaller systems and where building height is a concern. The 2880 has a higher membrane area within the same footprint, providing a more economical design.

DOW Ultrafiltration Modules can be utilized in a wide variety of treatment applications, such as surface water, seawater, and industrial and municipal wastewaters.

Product Specifications

Product | Type | Membrane Area | Hold-Up Volume | Weight (empty/water filled) |

|

| m2 | ft2 | liters | gallons | kg | lbs |

SFP-2860 | Industrial | 51 | 549 | 35 | 9.3 | 48/83 | 106/183 |

SFD-2860 | NSF/ANSI 61 Drinking Water | 51 | 549 | 35 | 9.3 | 48/83 | 106/183 |

SFP-2880 | Industrial | 77 | 829 | 39 | 10.3 | 61/100 | 135/220 |

SFD-2880 | NSF/ANSI 61 and 419 Drinking Water | 77 | 829 | 39 | 10.3 | 61/100 | 135/220 |

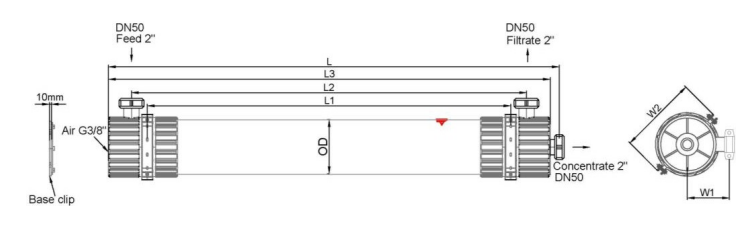

Figure 1 | SFP-2860, SFD-2860, SFP-2880, and SFD-2880 (8-inch diameter) |

Product | Units |

| Length |

| Diameter | Width |

|

| L | L1 | L2 | L3 | D | W1 | W2 |

SFP-2860 and SFD-2860 | SI (mm) | 1860±3 | 1500 | 1630±3 | 1820±3 | 225 | 180 | 342 |

US (inch) | 73.2±0.1 | 59.1 | 64.2±0.1 | 71.7±0.1 | 8.9 | 7.1 | 13.5 |

SFP-2880 and SFD-2880 | SI (mm) | 2360±3 | 2000 | 2130±3 | 2320±3 | 225 | 180 | 342 |

US (inch) | 92.9±0.1 | 78.7 | 83.9±0.1 | 91.3±0.1 | 8.9 | 7.1 | 13.5 |

Operating Limits

| SI Units | US Units |

Filtrate Flux (25ºC) | 40 – 90 l/m2hr | 24 – 53 gfd |

Flow Range Per Module1 | 2.0 – 6.9 m3/hr | 8.8 – 30.4 gpm |

Temperature | 1 – 40ºC | 34 – 104ºF |

Maximum Inlet Module Pressure (20ºC) | 6.25 bar | 90.65 psi |

Maximum Inlet Module Pressure (40ºC) | 4.75 bar | 68.89 psi |

Maximum Operating TMP | 2.1 bar | 30.5 psi |

Maximum Operating Air Scour Flow | 12 nm3/hr | 7.1 scfm |

Maximum Backwash Pressure | 2.5 bar | 36 psi |

Operating pH | 2 – 11 |

|

Maximum NaOCl | 2,000 mg/L |

|

Maximum Particle Size | 300 µ |

|

Flow Configuration | Outside in, dead end flow |

Expected Filtrate Turbidity | ≤ 0.1 NTU |

|

Expected Filtrate SDI | ≤ 2.5 |

|

1 Flow range represents DOW™ Ultrafiltration SFP-2860, SFD-2860, SFP-2880, and SFP-2880 Modules for filtrate flux range shown

Important Information

Proper start-up of an ultrafiltration system is essential to prepare the membranes for operating service and to prevent membrane damage. Following the proper start-up sequence also helps ensure that system operating parameters conform to design specifications so that system water quality and productivity goals can be achieved.

Before initiating system start-up procedures, membrane pretreatment, installation of the membrane modules, instrument calibration and other system checks should be completed.

For application cases, please click:https://www.fgwater.com/Industries/

For detailed parameters, please visit:

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.